OUR SOLUTIONS

One key solution might be smaller than you think

We call it ALL TIMES ENERGY Solution. Your BIO WASTE is the answer.

What is Biogas?

ALL TIMES ENERGY Solution has been designing and developing bio gas projects, reactivating dead biogas plants and maintenance contracts for biogas plants. We also provide consultation in all bio gas projects and supply equipment on most competitive prices.

What is Biogas?

When organic matters like; Agriculture, Animal(bovine and equine), Poultry, Municipal & Industrial biodegradable waste decompose in an oxygen free(anaerobic) environment it produces a gas commonly known as Biogas. This biogas mixture is mainly composed of methane 55% – 65%. This methane is a gaseous bio-fuel which can be used for generating heat and electrical energy.

Why Pakistan is most suited for production of biogas?

- Our economy is mostly agriculture based.

- Hot weather reduces the input energy cost for the production

- Large quantities of organic waste is being produced

- Cheap Labour

Advantages of Installing Biogas Plants For Dairy & Agricultural Farmers:

- Odor reduction and waste control

- Reduction of pathogenic germs

- Biogas for heating and electricity generation

- Bio-Fertilizer availability

- Reduction in fertilizer costs

- Reduction in energy & Irrigation cost

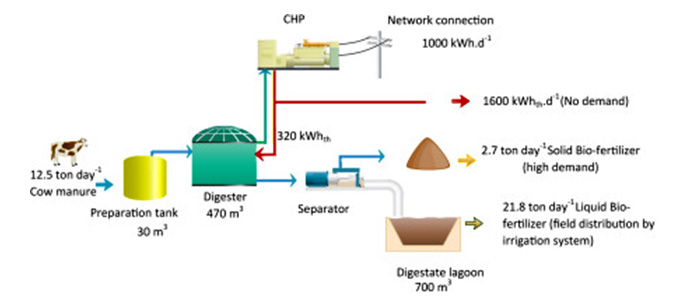

What is Lagoon Type BIOGAS Plant?

An anaerobic lagoon type biogas plant is a system designed to convert organic waste into biogas through the process of anaerobic digestion. Anaerobic lagoon type biogas plants are particularly suited for treating large volumes of organic waste, such as those generated by livestock operations or food processing facilities. They offer a cost-effective and environment friendly solution for waste management while producing renewable energy and valuable bio-fertilizer.

The layout of a lagoon type biogas energy plant is a complex process that should be carried out by a qualified engineer. However, the basic components and factors will provide a good starting point for the design.

Here is a diagram of the layout of a lagoon type biogas energy plant:

ALL TIMES ENERGY has an experience of fifteen years of a research base solution, operating a dairy farm of 300 plus cattle’s, providing green energy to a 200 acres organic farm and fulfilling bio fertilizer needs for the same farm.

How Do we Work

ALL TIMES ENERGY offers a complete turnkey solution of a lagoon base biogas plant from initial study to commissioning. We also provide consultancy in all aspects along with annual maintenance contracts.

Concept development and area study:

After study and inspection of the site we conduct a geological survey. We determine the energy potential based on available raw material data, prepare a technological scheme and then develop a financial proposal.

Project Design:

On the basis of area study and survey we make a layout plan according to the designated area for biogas plant. This design includes architectural layouts of every portion inclusive equipment configurations.

Civil work and Equipment installations:

Once project design is finalized the process of civil work starts. After marking the area, the execution team starts work. Once civil work completes as per design, the process of equipment installation and feeding of digester proceeds.

Project Testing & Commissioning

On completion of installation process, the project’s turnkey stage comes. Here the project is finally commissioned.

Aftersales services

For a turnkey base project we provide 6 months free of cost maintenance services to the clients.

Annual Maintenance contracts

Our company also provide annual maintenance facility to our clients for smooth project operations.

Revamping / Up gradation of Biogas PlantsWe also provide new life to your Failed Plants and up-gradation of old biogas plants.

Bio-Fertilizer

The slurry expelled from the digester is ready to use as valuable bio-fertilizer which can be stored or directly transferred to the agricultural fields for high yields. This bio-fertilizer also increases organic matter along with fertility of the soil.

According to a study one metric ton (MT) of cow dung can produce between 150 and 300 cubic meters (m3) of biogas.